2021年7月8日

Published by admin at 2021年7月8日

Categories

Automotive Plastic Parts M […]

2021年7月7日

Published by admin at 2021年7月7日

Categories

How to get a plastic injec […]

2021年6月24日

Published by admin at 2021年6月24日

Categories

6 Steps for Plastic Inject […]

2021年6月18日

Published by admin at 2021年6月18日

Categories

Automobile Industry Drive […]

2021年6月18日

Published by admin at 2021年6月18日

Categories

How is automotive plastic […]

2021年6月16日

Published by admin at 2021年6月16日

Categories

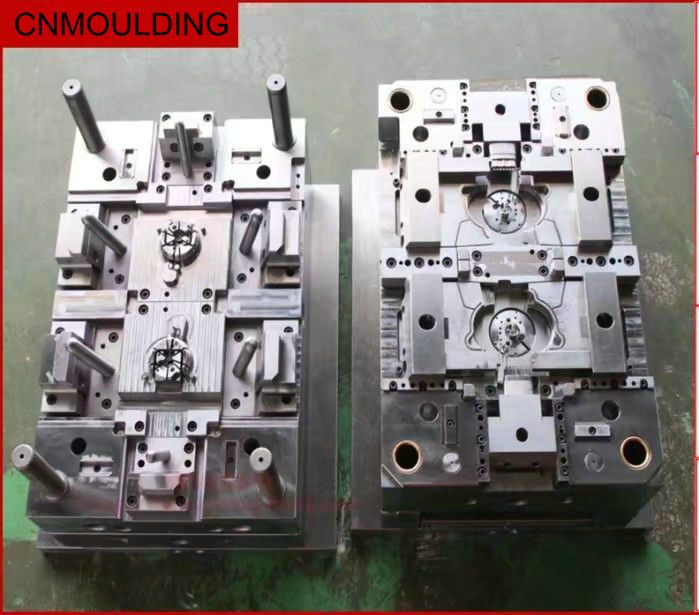

Refrigerator Mould CNMOULD […]

2021年6月14日

Plastic Injection Molding […]

2021年6月11日

Published by admin at 2021年6月11日

Categories

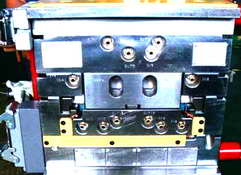

About Hot Runner Mould A h […]

2021年6月10日

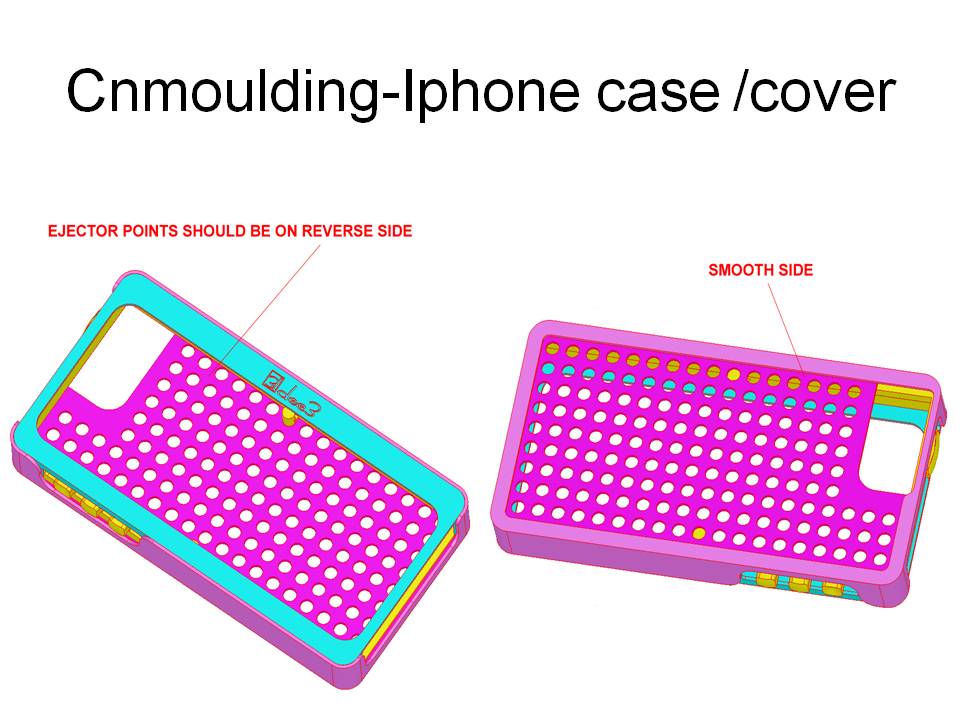

Accessories for your new i […]