China injection mold face greatest potential crisis

Precision Multi Cavity Injection Moulds Making

2020年8月31日

TPE Plastic

2020年9月1日China Injection mold face the greatest potential crisis

Cnmoulding engaged in injection molds and plastic injection molding products for 20 years. But in addition to the outstanding technical, a strong sense of the crisis is also necessary. The past two days, chat with a 12-years friendship customer, he came from the Netherlands. He told me that because of increasing labor costs in China.

Now sourcing product from China is very expensive. I have always thought that although the relationship between Japan and the Philippines is very good now. But china injection mold company have not many trade relations with these countries.

Because my client basically from Europe and the Americas, but now it seems that this idea is wrong. Because a large number of Japanese companies continue to move to the Philippines, Vietnam. there are political and economic reasons. my client’s customers are the large Japanese companies such as Hitachi, Toshiba.

Due to the technical content of china injection mold company has been very mature, will not be easy to be replaced by the company in Southeast Asia. It is only temporary, such as the Philippines, they have the communication skills. And very cheap labor costs will become increasingly powerful competitiveness.

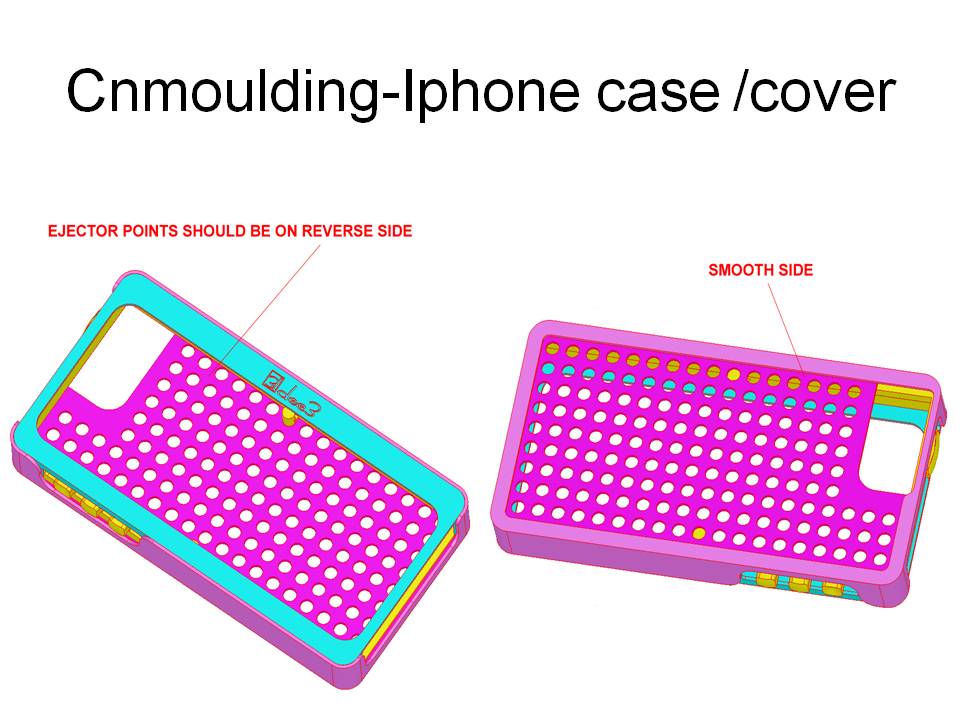

Today I read an article about the crisis in the manufacturing sector in China, I agree with this point very much. I have felt, and I believe it will snowball. I hope our new leaders play the greatest wisdom, deal with it all. I can not predict what will happen, but we can only work harder. Do much better plastic mold and injection molding products—see our hard job now

Attractive is the decline

Because of the rising costs in China, China’s injection mold company attractiveness is declining. The consumer goods manufacturing industry is turning to Southeast Asia, while the industrial manufacturing back to the U.S. However, the loss of manufacturing, the closing of the market. Production base into a star market new story has just begun.

A hovering four years of rumors will become a reality at the end of October. Adidas will close the last company in Suzhou, Jiangsu affiliated factory. Adidas also informed the other 10 foundries, OEM will continue to terminate the contract. Adidas’s strategy for global resources to reintegrate into the broad interpretation. its old rival Nike, in order to pursue a low-cost production base, moved out of China, more manufacturers will follow.

In addition to the clothes, shoe manufacturers began to leave. In the field of industrial manufacturing, China is also unattractive, while the United States has become the new destination of these investments. General Electric in the 2011 Annual Report, make home appliances production line to the United States to withdraw from China and Mexico. Ford will invest $ 16 billion in the United States increased factories and production lines. the world’s largest manufacturer of excavators and bulldozers Caterpillar 2011 Texas, USA to invest $ 120 million to create a new manufacturing plant.