Precision Injection Mold Manufacturer Industry Development In China

Plastic Molding Encyclopaedia

2021年5月21日

How to reduce the injection molding costs

2021年6月3日Precision injection mold manufacturer, the industry development is getting better in 2021

Many industries rising to the requirement of the mould, so precision injection mold manufacturing industry development gradually hot up. With the vigorous development of the electronic information industry and traditional industry informatization modification, the plastic mold market prospect of a vast, global high-grade. China’s precision injection mold manufacturer market is in a short supply situation.

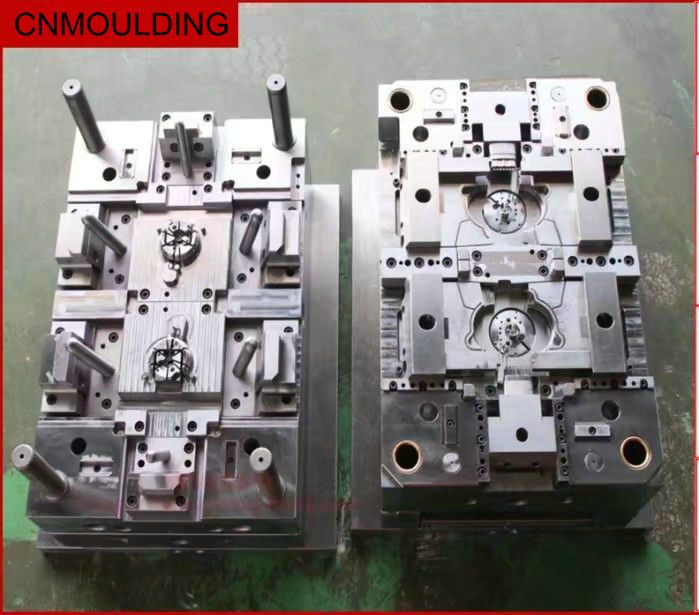

In the recent thirty years(since 1978), China’s plastic injection mold manufacturing level has been improved greatly. The production of the large single set weight of the plastic mould has reached more than 1500 tons. The accuracy of precision plastic injection mold making has reached 3 cm. It already can produce a multi-cavity mold, plastic mold cavity encapsulation molds,7800 high speed. Plastic molding has been able to produce more than 4 m / min high-speed plastic, different materials, plastic mold, and dual-color injection mold cavity.

i

National Policy Affecting Injection Mold Manufacturer

Affected by the variety of national policy and the continuous expansion of market space. The automotive industry, Injection Mold Manufacturer Industry, IT industry, home appliance industry, Medical industry, packaging industry momentum very rapidly in recent years. It is not only has made great development in terms of capacity but also in the aspect of the industry’s high-end has great progress. Therefore, the industry including the three aspects has strong injection mold manufacturing needs. Part of automobiles, IT products of plastic parts need to be all through the molding, eventually to become a finished product for sale.

With the rapid prototype mold development, the plastic industry and general engineering plastics in such aspects as strength unceasing enhancement. The application range of plastic products is also constantly expanding. The Amount of plastic products is also rising.

Precision Mold Manufacturer’s Technological application and innovation

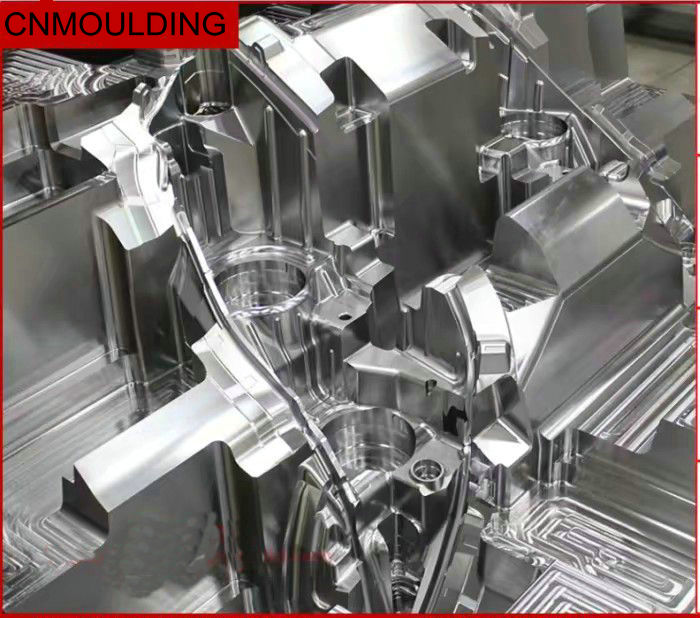

The development of injection mold manufacturers is getting better and better. It comes from the application and innovation of precision machining technology. Precision mold processing technology belongs to the precision machined parts industry. It contains a variety of precision tools and technology. The precision machines and parts, precision accessories and equipment, and other similar products. Such projects are unique. Because of custom design requests, production processing is also different. The perfect process attracts a large number of potential needs. We also look forward to providing quality injection mold manufacturing services to all through the magical online world and interactive opportunities.

Development trend of the mold industry

1.Progressive popularization and application of digital mold technology

Digital mold technology has been gradually applied in the mold design and manufacture in China. In recent years, domestic mold enterprises have begun to apply digital mold technology to mold development, design, manufacturing and testing, improving the reliability of mold design, shorten the mold development cycle and achieved good economic benefits. It is expected that digital mold technology will gradually become the mainstream technology of mold manufacturing, and will be adopted by more mold enterprises.

2. Laser Rapid Prototyping Technology for Mould Manufacturing

Compared with the traditional molding technology, the laser rapid molding technology has the advantages of high raw material utilization rate (nearly 100% ), applicable complex structure, easy integration and intelligence, which is the ideal molding process of the mold. Laser forming technology such as laser sheet laminate manufacturing technology LOM、 selective laser sintering technology. SLS has been successfully used in mold manufacturing. Laser rapid molding technology has broad application prospects in automobile mold manufacturing and is one of the important development directions of mold molding technology.

3.Industrial transfer and global procurement bring new development opportunities

After years of development in China’s mold manufacturing industry, its overall strength and comprehensive competitiveness have been significantly enhanced. The service capacity of the downstream industries has been greatly improved. The technical level and product quality of the mold have been greatly improved. A number of top injection molding mold companies represented by CNMOULDING with strong strength have emerged, and foreign downstream manufacturers went to China to purchase molds in China. China’s mold manufacturing industry has ushered in a new round of development opportunities.