Everything about plastic injection molding is here

Guide Cn-Moulding company

How about custom Plastic Injection Molding Feature

Plastic Injection Molding Glossary

Transparent parts

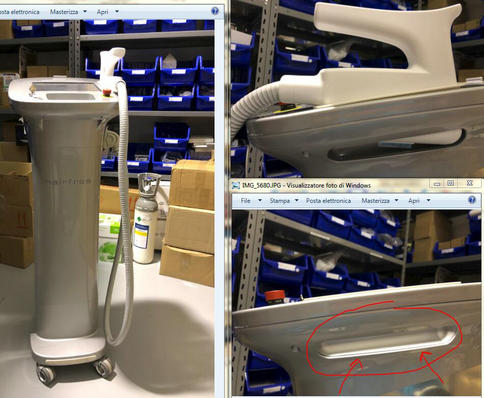

Medical components

Medical components

Plastic Parts, Plastic Products, Plastic Components Making solution

- Combines over 20 years of practical experience in plastic injection molding with continued investment in technological innovation to ensure that we produce exceptional results for our customers.

- Our focus is on your success. Whether through innovative proprietary products or practical

- Injection molding manufacturing solutions to your design concepts, precisely meeting your needs is

- Our scientific molding process assures high levels of consistent quality and is the top priority.

- Supported by our in-house tool shop and free lifetime maintenance on many molds.

We manufacture and distribute auto parts , Plastic Closure, Plastic Strip, Plastic Shell for your choice for a wide range of industries and applications. In china molding plastics’ 20 year history, we have injection-molded plastic parts in every available plastic shape. We have extensive resources for locating even difficult to find material or help with coordinating custom plastic parts runs.

Don’t pay overseas prices when you can get a bargain here at home. To hire a quality provider of plastics according to your design specifications, contact china molding supplier now.

Plastic Injection Molding Service list

- Plastic part fabrication

- Custom insert molding

- Precision mold making

- Overmolding

- Custom Plastic Fabrication

Injection molding is used to produce thin-walled plastic parts for a wide variety of applications, one of the most common being plastic housings. The plastic housing is a thin-walled enclosure, often requiring many ribs and bosses on the interior. These housings are used in a variety of products including household appliances, consumer electronics, power tools, and automotive dashboards. Other common thin-walled products include different types of open containers, such as food boxes. Injection molding is also used to produce several household items such as transparent parts or over-molding toothbrushes. Many medical devices, including valves and syringes, are manufactured using injection molding as well.

| Typical | Feasible | |

| Shapes : | Thin-walled: Cylindrical Thin-walled: Cubic Thin-walled: Complex | Flat |

| Part size: | Envelope: 0.01 in³-80 ft³ Weight: 0.5 oz-55 lb | |

| Materials: | Thermoplastics | Composites Elastomer Thermosets |

| Surface finish-Ra : | 4-16 μin | 1-32 μin |

| Tolerance : | ± 0.008 in. | ± 0.002 in. |

| Max wall thickness : | 0.03-0.25 in. | 0.015-0.5 in. |

| Quantity : | 10000-1000000 | 1000-1000000 |

| Lead time : | Months | Weeks |

| Advantages: | Fabricate complex shapes Excellent surface polish. High critical accuracy. High production rate. Low labor cost Scrap can be recycled | |

| Disadvantages: | Limited to thin-walled parts. High tooling and equipment cost Long lead time possible | |

| Applications: | Medical, Automotive, Machining, etc., | |