Evaluation standard of high quality plastic mold company in China

Advantages of plastic medical instrument

2020年7月13日

China injection molding income situation

2020年7月18日Evaluation standard of high-quality plastic mold company in China

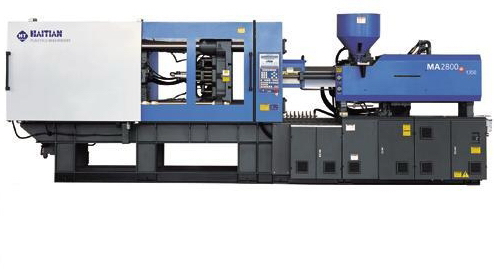

Cnmoulding plastics mold company. A china leader in custom injection molded plastics manufacturing. We announced have to buy one new Haitian 100-ton injection molding presses. With the addition of the new presses. Cnmoulding has injection molding presses ranging in size from 60 tons to 650 tons. The new presses will be used to substantially expand the company’s services in a variety of areas for the benefit of our customers.

“Investment in our new machine provides us with an increased capacity, as well as by increasing our ability to grow. We try to continue to improve, always stand in the peak of science and technology. And strive for the interests of customers. Mold quality is the foundation of our success, 100% of our new plastic molds only take 1 time or 2 times testing before we put them into mass production or send to oversea customers.

From materials incoming to finished workpiece before mold assembly, we have a fully implemented quality control process to ensure lower re-work rate, lower wastage, high efficient and short delivery term. From the first article inspection to process capabilities study. We guarantee production is stable and correct.

All mold steel/resin we used is strictly following customers’ quality requirements, steel purchased certificates and property specification of plastic raw materials are always available.” said Cnmoulding plastics manager, kennyhan. “It is yet another example of our commitment to producing injection-molded plastic products of the highest quality.”

Luxury sports car maker Aston Martin has announced a global recall

Aston Martin ignores its internal processes for a range of procurement, vendor and product monitoring problems. Since November 2019 produced a total of 17,590 sports car, called the discovery of parts of China. The production of sub-suppliers in Shenzhen KEXIANG mold company uses fake plastic material. In this regard, caught in a storm in Shenzhen KEXIANG mold company responsible Ang Zhang announced that denies its production, Aston Martin.

Over parts, China has a lot of plastic injection mold company and products manufacturer. They serve different target customers, some companies large scale, but the basic outsourcing. In fact, customers need to find is a real experience, and provide a long-term senior custom mold for overseas customers and plastic products suppliers.

CNMOULDING no doubt that customers really need to find manufacturers. Since its establishment in 1997, the years from different companies for their commitment. Who were providing quality automotive parts, medical equipment, industrial supplies, electronic components, small appliances mold design and manufacture of plastic products processing factories?! The company currently employs 80 people, The significance of the quality of the enterprise:

Quality control in china mold company

Parts made in a plastic injection molding process can have their own unique set of possible defects. That is why all of our employees are trained to spot these problems. The following is a listing of the most common defects associated with the plastic injection molding and transfer/compression molding processes.

Sink Marks: Sinking is caused by the outer skin of plastic solidifying while the material inside is still molten and viscous. As it cools and solidifies, the material compacts. The best way to avoid these dimples is to design the part with consistent wall thickness. However, many times the effect of the sink mark can be minimized by adjusting molding parameters such as injection pressure and time.

Gas marks (burning): When molten plastic is injected into a mold cavity. The air that is in that cavity needs a place to escape. If the hot compressed air cannot escape, it may leave a burn mark on the part. The best way to avoid gas marks is to strategically locate air vents of the proper depth within the mold. Adjustments to process parameters such as injection speed and screw speed can be altered to reduce or eliminate burning.