Hardened Mould&Tools

The disadvantage of hot runner

2019年11月5日

Undercuts

2020年6月23日Why we can make the best quality hardened the mold

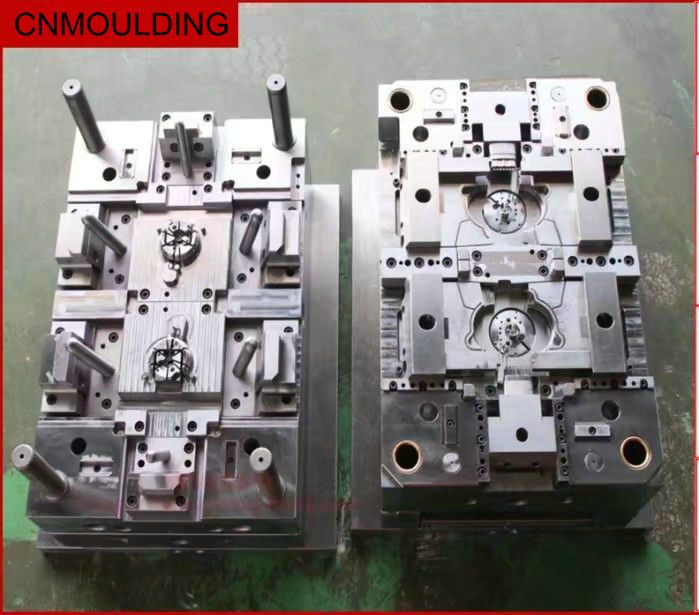

We make a full hardened mould for injection moulding and plastic Injection. We can increase the steel hardness by various means of heating the system in a short time from the use of general-purpose mold material. It is clear that high-end molds have come up with a problem that is easy to solve, and we use the latest processing equipment and design concepts to provide customers with the perfect mold.

Molded parts are widely used in auto accessories, Electronics, household appliances, medical devices, game players, and computer displays fields. Be A professional Injection Mold Factory in China, we promise to custom is Supply Best Quality which exceeds our client’s needs and expectations.

Propose Best Cost Save plan to our clients. Provide Best Delivery Schedule & Implement to ensure our clients get when they expected to get. And we use the best quality mold steel to make a full hardened mould for our customers.

H13 OR 2344

The properties of Hot Work Steels are matched specifically to high-temperature applications. Typical fields of use for hot work steels include: Die casting, extrusion, Die forging, glass processing, and tube and pipe manufacture.

Thyrotherm 2344 Magnum is an electro slag remelted hot work tool steel, designed to meet all premium H13 specifications. The increased toughness of this material was developed to meet the most stringent die casting applications. Thyrotherm 2344 Magnum differs from Thyrotherm 2344 SUPRA by using specially selected input materials, controlled forging, and special thermal procedures.

NAK80

NAK80 is a 40 HRC pre-Hardened, high performance, high precision, mold steel. Applications include plastic molds, rubber molds, jigs & fixtures, and press dies.

Features:

Machines up to 20 percent faster than 30 HRc P20

Pre-hardened to 38-42 HRC

Uniform microstructure & hardness (40 HRC between surface & interior)

Never needs stress relieving, even after heavy machining

Highly weldable, HAZ gets softer not harder (re-age harden to bring back to 40 HRC)

EDM layer is easy to remove