The disadvantage of hot runner

Clear plastic injection molding

2019年10月21日

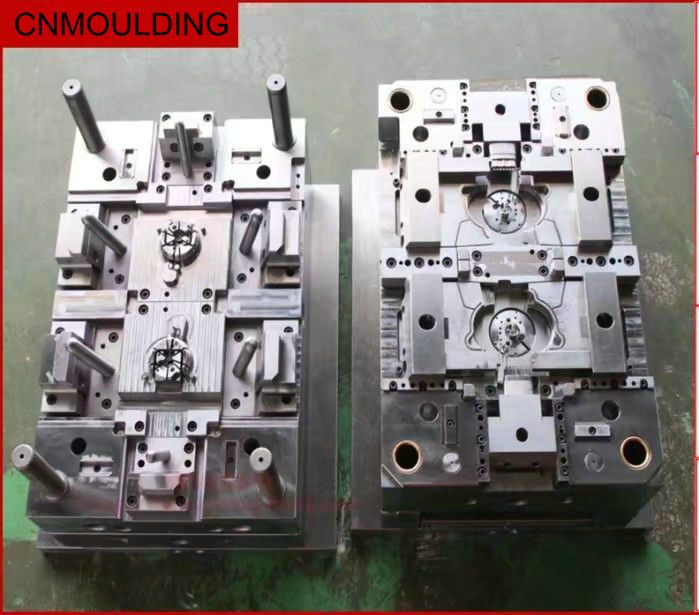

Hardened Mould&Tools

2019年11月7日The injection mold of hot runner disadvantage

All of the injection mold makers know hot runner injection mold has many significant advantages. The mold maker also needs to understand the shortcomings of the hot-runner injection mold. How it will cause mold costs rising, more mold production facility requirement and maintenance complex. Summed up in the following points.

1, mold rising costs

Hot-runner components are more expensive than other injection mold popular accessories, it causes injection mold costs may be substantially higher. If the production of a small plastic workpiece, cost-sharing on the mold a high proportion. Do not spend the economic operator. Hot-runner systems expensive plastic mold injection users of many developing countries, affecting one of the main problems of injection are widely used in your industrial system.

2, The mold production facility requirements

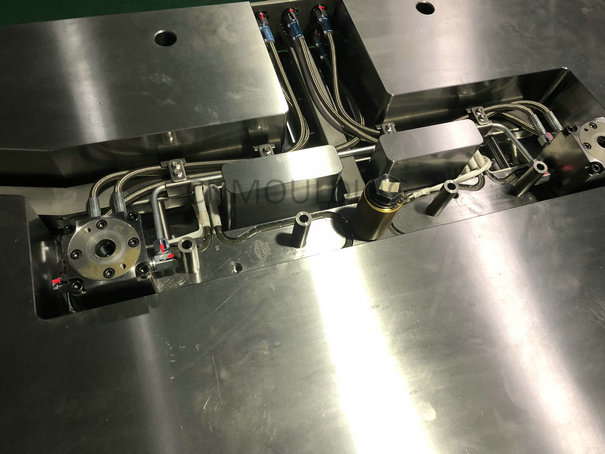

An injection mold requires a precision machining mechanical guarantee. The whole system and mold integration and coordination requirements are extremely strict, otherwise the mold there will be a lot of serious problems in the production process. Bad cause the plastic overflow damage to the runner components interrupts production such as mold and hot-runner sealed plastic bits sealing nozzle inserts and the gate relative position bad led to a serious decline in quality of the products.

3, operation and maintenance complex

Compared with the cold runner mold, this kind of mold operation and maintenance of up more complex than the cold runner mold. Such as the improper use of operating easily damaged plastic molding parts, so that production can not be carried out, resulting in huge economic losses. New user manufacturing mold, take a long time to accumulate experience. Or manufacturing company to arrange for a technician to the site to explain the installation and removal Note!

Former engineering design should pay attention to what matters, advanced system installation openings attention to what matters to mid-tooling. The late injection tryout use to pay attention to what matters to the mass use of hot runner system maintenance/repair Note! Personnel training … professional mold design; whole system installation. Tryout. Maintenance. Maintenance professional consulting services