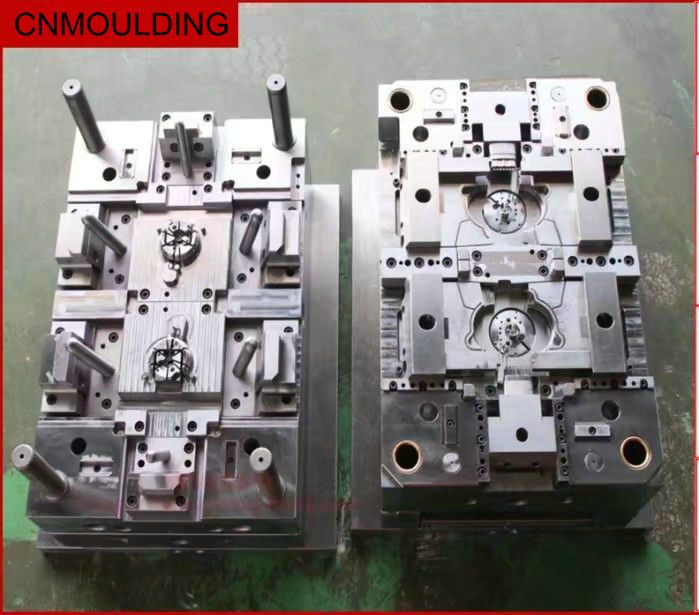

mold slider

Tough mold manufacturing industry

2020年8月3日

Polyetherimide Material

2020年8月12日China company design mold slider overview

When the sidewall of the plastic molding products with a hole recess boss, plastic injection molding products do not directly emerge from the injection molds forming holes. The grooves and bosses molded parts must be made of the activities, known as core activities mold slider. Completion of the activity type out and reset mechanism called pumping institutions.

(A) Classification of mold slider core-pulling mechanism

- China mold slider motor core pulling, rely on the action of the inspection injection mold. A core-pulling machine with the active core, the core extraction. Core pulling motor with large ejection force, labor intensity, high productivity and easy to operate. It was widely used in production. Their transmission mechanism can be divided into the following categories. bevel pillar core oblique block core pulling, rack and pinion core pulling.

- Manual pumping core mold slider, relying on humans to extract core activities either directly or through pass parts. The disadvantage is that production, labor-intensive, and restricted. It is difficult to get a large core pulling force. The advantage of the mold slider structure is simple, easy to manufacture. The manufacturing mold cycle is short, suitable for the trial and small batch production of plastic products. Characteristics of plastic parts limitations, can not use the motor core pulling, you must manually pumping the core. Manual core pulling their transmission mechanism can be divided into the following categories. A screw mechanism core pulling, rack and pinion core pulling activities insert core, core-pulling.

- Hydraulic pumping the core of the core activities, relying on the hydraulic cylinder. And its advantages can be replaced according to the size of the ejection force and the length of the core-pulling distance the core hydraulics, to get a larger ejection force and longer pulling distance. Due to the use of high-pressure liquid as the driving force transfer smooth. The disadvantage is that the operation process, but also the whole set of hydraulic core pulling device. Therefore, its use is limited in scope, it seldom used.

(B) Mold slider core-pulling distance and the calculation of the ejection force

Core from the plastic molding monk pumped without prejudice to the plastic products prolapse of the monk. That core pulls in the direction of the distance, called mold slider core-pulling distance. Pulling distance should be equal to the molding hole depth plus 2-3 mm.

Mold slider pulling distance calculation

Calculated as follows:

To S = Htgθ (3-26)

Where

S —— pulling distance (MM)

The H —— oblique guide posts required to complete the core pulling stroke (MM)

theta —– oblique angle of inclination of the guidepost, and generally 15 · 20 ·

The calculation of the ejection force plastic products in the cooling package tight core, resulting in the force of the package tight. To the core extracted, must overcome the resistance of the friction caused by the package tight force, This force is called the ejection force at the beginning of mold core pulling, the moment required release force.

Affect the ejection force of many factors, broadly summarized as follows;

- Core forming part of the surface area and cross-sectional geometry. A core molding part of the area is a large, wrap-tightening force. The mold clamping force the product shape of the cross-sectional area of the core, including the tightening force is small. And also it’s releasing. The core cross-sectional shape is rectangular or curved, package shipping force. the release force is also large.

- The plastic shrinkage, coefficient of friction and rigidity: The plastic shrinkage, large clamping force on the core package, the release force is also large; good surface lubricity performance plastics, the release force is small; soft plastic, hard plastic required ejection force small.

- The wall thickness of the plastic products: inclusive area of the same size plastic products, thin-walled plastic products shrinkage, the ejection force is also small shrinkage; captured wall plastic products, mold release force.

- Plastic products the same side at the same time the number of core-pulling: When plastic products have more than two hole slot on the same side of the pumping mechanism pulls into plastic products have more than two of the same side of the hole slot, the use of sampling World institutions at the same time pulls, due to the contraction of plastic products Pitch, the ejection force.

- The active core molding surface roughness: the active core molding surface of the contact surface of the plastic article Pulling relative friction against the release force, have a great impact, therefore, the injection molder surface should be smaller roughness (usually Rα0.4um), processing of grain to the requirements and pulls in the same direction.

- China mold slider process: injection pressure, dwell time, cooling time for the ejection force. When the injection size, dwell time is short of the ejection force. Long cooling time, condensing contraction of plastic products is substantially complete. The packages tight force, ejection force.

Under the influence of various factors, the ejection force computing power formula is as follows

F = Lhp (u * cosα-sinα)

Wherein F —- ejection force (N)

The L — core activities are the cross-sectional shape of the plastic products package tight perimeter (MM)

H — forming part of the depth (MM)

P — unit area packet clamping force, and generally … 12Pa;

u — friction slope (°)